Highly Reliable PCBs for Vehicles & E-Mobility

Automotive PCBs are specially designed circuit boards that meet the extreme demands in vehicles, e-mobility, and autonomous driving systems. They must withstand high temperatures, mechanical stress, moisture, vibrations, and electromagnetic interference. With the increasing electrification of vehicles and the transition to autonomous systems, highly complex PCB technologies are gaining importance. Modern automobiles contain up to 100 electronic control units (ECUs) that require reliable signal transmission.

Applications

PCBs are essential for vehicle control and are used in five main areas. They regulate engine and drivetrain systems, optimizing performance and emissions. In safety and assistance systems, they enable functions such as ABS, ESP, and airbags. Infotainment and communication solutions rely on PCBs to control displays, audio, and networking. They are also responsible for modern LED lighting systems and energy management in electric vehicles.

-

Drive & Motor Control

PCBs control motor functions such as ignition, injection, and transmission adaptation, optimizing performance and reducing emissions.

-

Safety & Assistance Systems

They enable vital functions like ABS, ESP, airbag control, and driver assistance systems for enhanced safety.

-

Infotainment & Communication

PCBs form the basis for touchscreens, audio, navigation, and connectivity systems like Bluetooth and vehicle-to-vehicle communication.

-

Lighting Systems

They control modern LED headlights, adaptive lighting systems, and interior lighting for better visibility and driving comfort.

-

Electromobility

PCBs regulate battery management, inverters, and charging electronics to ensure efficient energy distribution in electric and hybrid vehicles.

Frequently asked questions

-

Battery management systems (BMS) and high-performance inverters require strong copper layers (up to 400 μm) to safely conduct high currents.

-

Through conformal coating, special solder masks, and selective protective coatings, the PCB is protected against moisture, dust, and corrosion.

-

Our PCBs meet IATF 16949 (automotive standard), IPC-6012 Class 3, and AEC-Q200 for electronic components.

-

Modern vehicle systems contain many high-frequency components. By optimizing ground planes, differential signal lines, and EMC design guidelines, interferences are minimized.

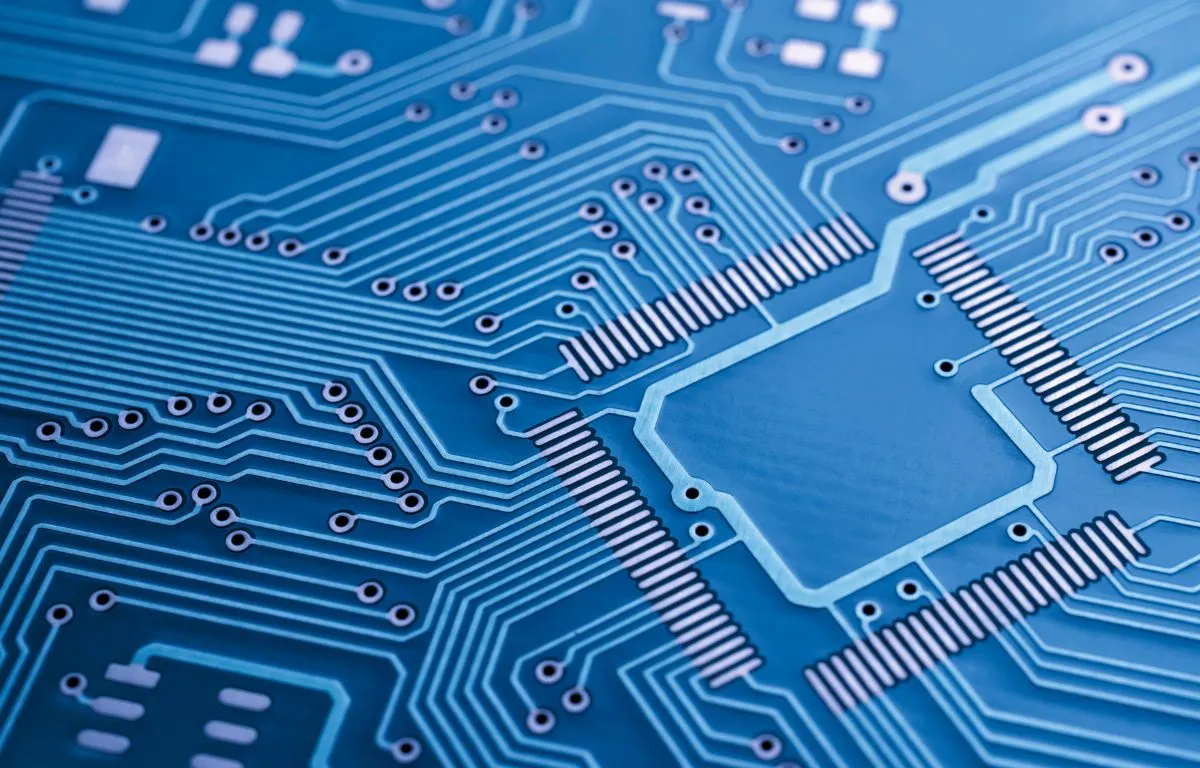

Common Materials used in Automotive Industry

PCBs in the automotive industry are made from materials like FR4 (standard epoxy), metal core PCBs for better heat dissipation, flexible polyimide PCBs for space-saving applications, and ceramic PCBs for high-temperature areas. These materials ensure durability, resilience, and efficient electrical performance in vehicles.

- FR-4 PCBs

- FR-4 is the most widely used base material in PCB manufacturing. It is a glass-reinforced epoxy laminate offering high mechanical strength, excellent electrical insulation, and very good temperature resistance. The term "FR" (Flame Retardant) indicates that the material is flame resistant and meets the UL94 V-0 standard.

- Polyimide PCBs

- Polyimide PCBs are made from a special plastic material with high temperature resistance, excellent flexibility, and extraordinary mechanical stability. Unlike FR-4 materials, polyimide PCBs are extremely resistant to heat, chemicals, and mechanical stress, making them the preferred choice for high-performance and flexible applications.

- Ceramic PCB

- Ceramic PCBs consist of ceramic substrates such as aluminum oxide (Al�02O�03) or aluminum nitride (AlN), offering extremely high thermal conductivity, excellent electrical insulation, and outstanding mechanical stability. Compared to conventional FR-4 PCBs, ceramic PCB board are ideal for high-power applications requiring efficient heat dissipation and exceptional reliability.