High-Performance PCBs for Efficient Lighting Systems

LED PCBs are specially designed circuit boards for light-emitting diodes (LEDs) that enable efficient heat dissipation. Since LEDs are sensitive to temperature increases, metal core PCBs (MCPCB) with aluminum or copper bases are preferred to ensure optimal cooling and extend the lifespan of the LEDs. With the increasing electrification of vehicles and the transition to autonomous systems, highly complex PCB technologies are gaining importance. Modern automobiles contain up to 100 electronic control units (ECUs) that require reliable signal transmission.

Applications

PCBs are crucial for controlling and dissipating heat from LEDs in vehicles, particularly in lighting systems such as headlights, taillights, and interior lighting. They ensure efficient light distribution and longevity of LED components by dissipating heat and providing stable electrical performance. Especially in modern vehicles that rely on energy-efficient and durable lighting, specially developed metal core PCBs are used to efficiently dissipate heat from LEDs.

-

Automotive Lighting

PCBs control and cool LED headlights, taillights, daytime running lights, and interior lighting in vehicles.

-

Display and Indicator Lighting

PCBs are used to operate LEDs in digital signboards, information displays, and vehicle indicators.

-

Office and Street Lighting

In modern LED office and street lighting, PCBs ensure energy efficiency and longevity.

-

Consumer Electronics

PCBs enable efficient LED lighting function in devices like televisions, monitors, and household appliances.

-

LED Panels and Fixtures

In industrial applications and decorative purposes, PCBs in LED panels and fixtures ensure uniform lighting and heat dissipation.

Frequently asked questions

-

LEDs lose a significant portion of their energy as heat. Without effective cooling, this can significantly shorten lifespan and reduce luminous efficacy.

-

The most common materials are aluminum (MCPCB), copper & FR-4 with special thermal conductivity.

-

ENIG (Electroless Nickel Immersion Gold) and HASL (Hot Air Solder Leveling) offer the best combination of durability and electrical conductivity.

-

Yes, flexible LED PCBs are perfect for curved surfaces, architectural solutions & portable lighting systems.

-

For high-current LEDs, thicker copper layers (35 μm to 400 μm) are recommended to optimize current flow and ensure even heat distribution.

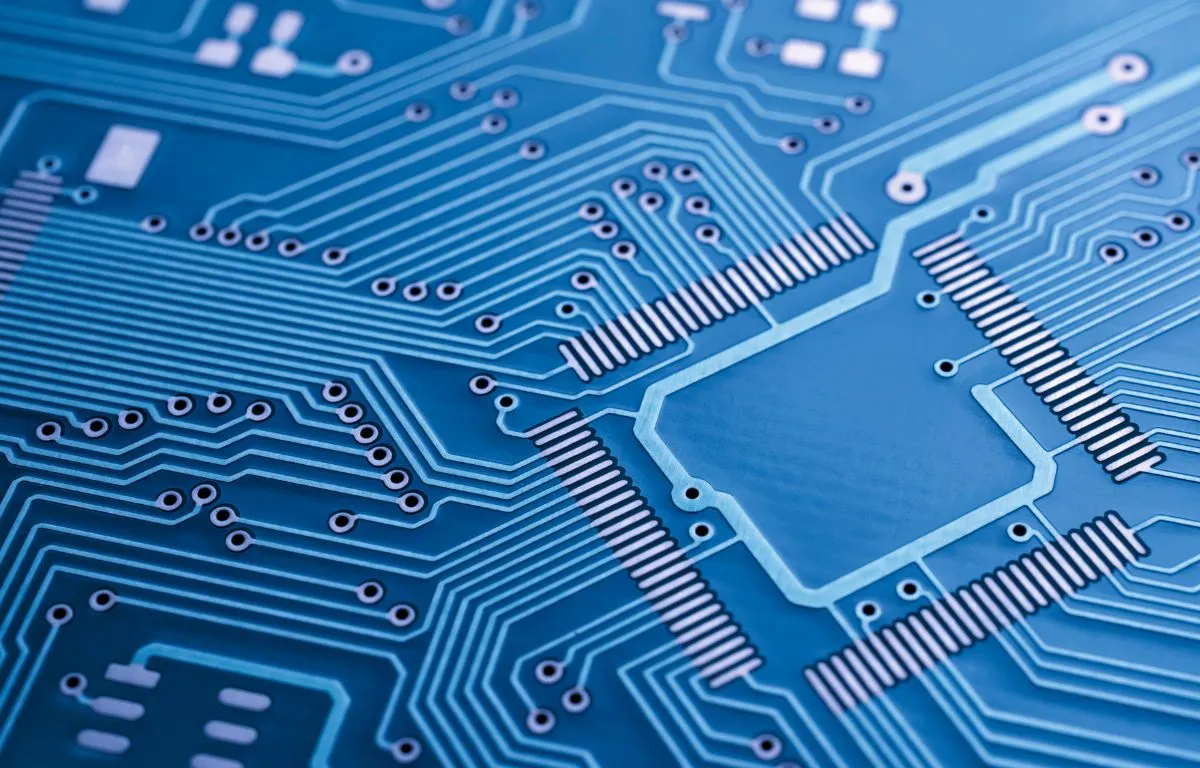

Common Materials used in LED Technology

For LED-based PCBs, metal core PCBs (MCPCBs) are mainly used because they provide excellent heat dissipation. Materials such as aluminum or copper are typically chosen as core materials. FR4-based materials can also be used, but for intense heat sources, ceramic PCBs are a preferred choice due to their higher temperature resistance. These materials provide the necessary stability to operate LED components efficiently and sustainably.

- Copper-based PCBs

- Copper-based PCBs consist of a metal core structure with a solid or coated copper layer offering superior thermal conductivity and high electrical performance. Compared to FR-4 or aluminum PCBs, copper PCBs provide even more efficient heat dissipation, making them ideal for power electronics, high-current applications, and high-power LEDs.

- FR-4 PCBs

- FR-4 is the most widely used base material in PCB manufacturing. It is a glass-reinforced epoxy laminate offering high mechanical strength, excellent electrical insulation, and very good temperature resistance. The term "FR" (Flame Retardant) indicates that the material is flame resistant and meets the UL94 V-0 standard.

- Ceramic PCB

- Ceramic PCBs consist of ceramic substrates such as aluminum oxide (Al�02O�03) or aluminum nitride (AlN), offering extremely high thermal conductivity, excellent electrical insulation, and outstanding mechanical stability. Compared to conventional FR-4 PCBs, ceramic PCB board are ideal for high-power applications requiring efficient heat dissipation and exceptional reliability.