High-Precision PCBs for Radar & Sensor Technology

Radar PCBs are special high-frequency circuit boards optimized for detecting, processing, and transmitting radar waves. They play a crucial role in automotive, aerospace, security surveillance, and industrial automation. Radar technology requires high precision, minimized signal losses, and controlled impedance, which is why radar PCBs are made from high-frequency materials such as Rogers, PTFE (Teflon), Isola, or Taconic.

Applications

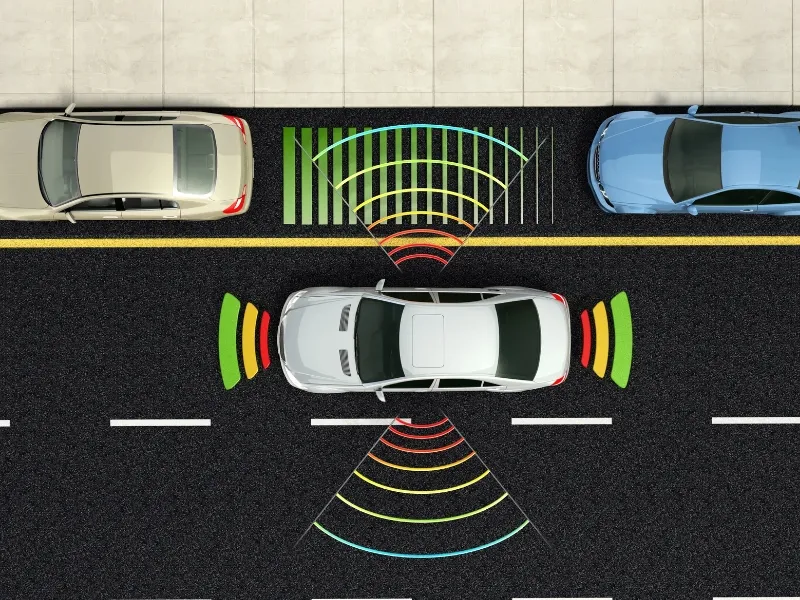

PCBs are a key technology for radar systems in vehicles, essential for advanced driver assistance systems (ADAS) and autonomous driving. Radar is used to detect objects in the vehicle's surroundings, measure distances, and monitor the movements of other road users. In this area, PCBs are used for signal processing and transmission in radar sensors necessary for functions like emergency braking assist, lane-keeping assist, and collision avoidance.

-

Driver Assistance Systems

PCBs control radar sensors for systems like emergency braking assistants, distance control, and lane-keeping assistants that enhance vehicle safety.

-

Autonomous Driving

Radar PCBs enable precise environment recognition and object detection necessary for autonomous driving.

-

Parking Assistance Systems

Radar sensors controlled by PCBs help detect obstacles and assist in parking maneuvers.

-

Collision Avoidance Systems

Radar PCBs are crucial for monitoring nearby vehicles and preventing collisions.

-

Traffic Monitoring Systems

PCBs control radar in systems for monitoring traffic flow and vehicle speeds on the road.

Frequently asked questions

-

Standard FR-4 has higher losses, negatively affecting radar range and signal quality. Therefore, Rogers, PTFE, Isola & Taconic are used.

-

We manufacture radar PCBs for 24 GHz (short-range radar), 77 GHz (automotive) & 120 GHz (millimeter-wave applications).

-

Controlled impedance for interference-free signal transmission, multilayer structures for complex high-frequency circuits, special routing & ground planes to minimize EMC interferences.

-

Our PCBs are equipped with conformal coating, special protective lacquers & potted modules to protect them against temperature, moisture & dust.

-

Modern vehicles use 77 GHz radar PCBs with multilayer technology for vehicle detection, lane-keeping & emergency braking systems.

Common Materials used in Radar Systems

For radar PCBs, high-frequency-capable materials like PTFE (Teflon) or Rogers materials are often used, specifically designed for high-frequency applications and offering low attenuation and high stability at high frequencies. FR4 materials can also be used but in less demanding radar applications. To optimize signal transmission and reception performance, metal core PCBs are also a common choice as they offer excellent heat dissipation in addition to electrical performance.

- Rogers PCB

- Rogers PCBs are made from high-quality, high-performance laminates specifically designed for high-frequency and high-speed applications. Unlike standard FR-4 materials, Rogers laminates offer improved dielectric constant, lower losses, and better thermal performance. These properties make them the ideal choice for RF (Radio Frequency), microwave communication, and high-frequency power electronics.

- FR-4 PCBs

- FR-4 is the most widely used base material in PCB manufacturing. It is a glass-reinforced epoxy laminate offering high mechanical strength, excellent electrical insulation, and very good temperature resistance. The term "FR" (Flame Retardant) indicates that the material is flame resistant and meets the UL94 V-0 standard.