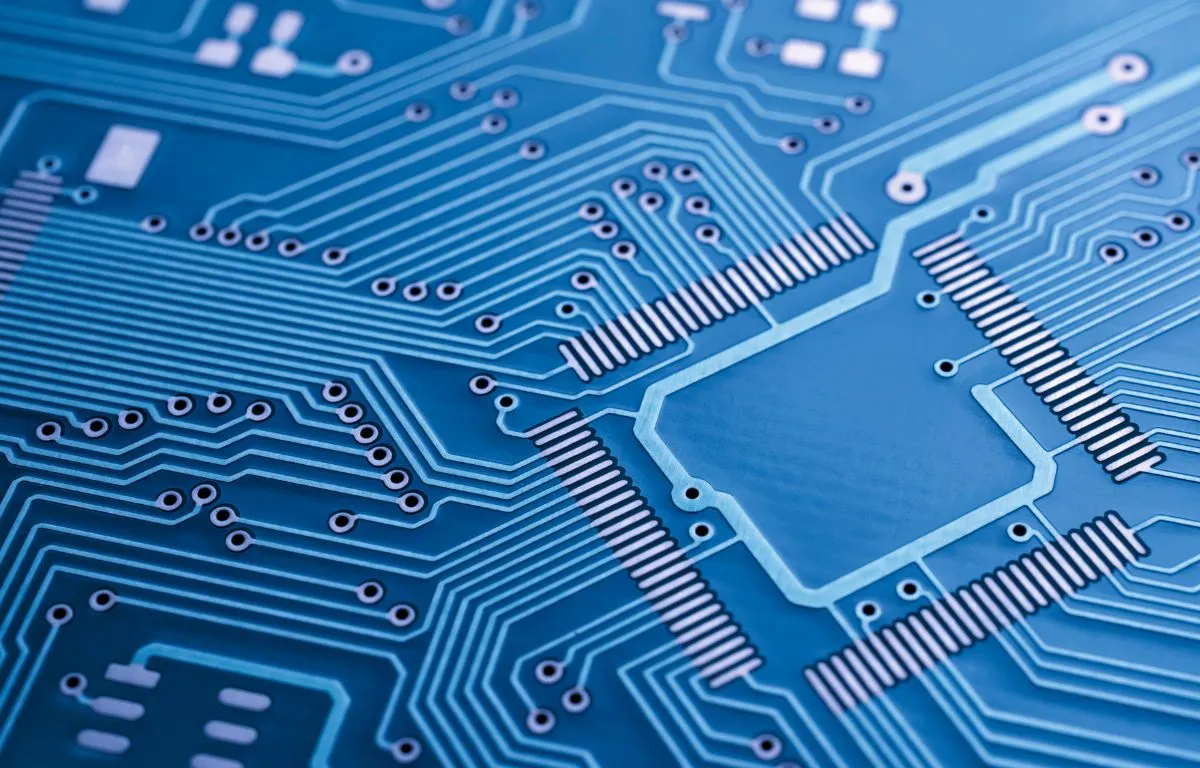

High-Precision PCBs for Sensor & Measurement Systems

Sensor PCBs are specially designed circuit boards for measurement, analysis, and sensor technologies. They are the core of many applications, including IoT, medical technology, automotive, aerospace, and Industry 4.0. Sensor circuit boards often need to be highly sensitive, miniaturized, and robust against environmental influences. They must precisely capture and process data, making high signal integrity, EMC protection, and temperature resistance essential.

.webp)

.webp)

Applications

PCBs play a central role in sensor technology by enabling the control and evaluation of sensor data. In vehicles, they are used in various sensors, such as temperature, pressure, motion, air quality, and humidity sensors, all of which are important for the functionality of driver assistance systems, comfort features, and environmental management systems. They ensure that the sensors operate reliably and precisely by capturing, processing, and transmitting data to other vehicle components.

-

Vehicle Sensors

PCBs control sensors such as ultrasonic, radar, and camera systems for safety and driver assistance functions like parking aids and autonomous driving.

-

Temperature and Pressure Sensors

In vehicles, PCBs monitor sensors for temperature and pressure measurement for engines, air conditioning, and tire pressure monitoring systems.

-

Air Quality and Emission Sensors

They are crucial for monitoring air quality and exhaust emissions, optimizing vehicle performance and environmental regulations.

-

Motion and Proximity Sensors

PCBs control sensors detecting motion or proximity, integrated into safety and comfort systems like keyless entry and alarm systems.

-

Humidity Sensors

In vehicles, they monitor cabin humidity or dehumidification systems to enhance driving comfort and protect vehicle components.

Frequently asked questions

-

Depending on the application, HDI, flexible PCBs, RF PCBs & multilayer designs are particularly suitable for sensor technology.

-

Through conformal coating, protective lacquers & potted PCB technologies, sensors can be protected against moisture, dust & temperature.

-

For precise sensor applications, we use FR-4, polyimide, Rogers, PTFE & metal core PCBs depending on thermal & electrical requirements.

-

Automotive sensors must withstand high temperatures, vibrations & electromagnetic interferences, which is why high-Tg materials & EMC-optimized layouts are used.

-

Yes, flex and rigid-flex PCBs are ideal for wearable sensors as they are space-saving, lightweight, and flexible.

Common Materials used in Sensor Technology

For sensor PCBs, FR4 materials are often used because they provide good mechanical properties and cost-effective production. In highly sensitive applications, such as pressure or temperature sensors, ceramic PCBs can be used as they offer higher temperature resistance and more precise measurements. Flex PCBs are used in applications where the sensor must be installed in complex or confined spaces, such as in vehicle components or to avoid complex cable routing.

- FR-4 PCBs

- FR-4 is the most widely used base material in PCB manufacturing. It is a glass-reinforced epoxy laminate offering high mechanical strength, excellent electrical insulation, and very good temperature resistance. The term "FR" (Flame Retardant) indicates that the material is flame resistant and meets the UL94 V-0 standard.

- Ceramic PCB

- Ceramic PCBs consist of ceramic substrates such as aluminum oxide (Al�02O�03) or aluminum nitride (AlN), offering extremely high thermal conductivity, excellent electrical insulation, and outstanding mechanical stability. Compared to conventional FR-4 PCBs, ceramic PCB board are ideal for high-power applications requiring efficient heat dissipation and exceptional reliability.

- Semiflex PCB

- Semiflex PCBs are partially flexible circuit boards that can be bent over defined areas while the rest of the board remains rigid. This technology allows space-saving, reduces connectors, and improves the reliability of electronic systems. Semiflexible PCBs are often used as a cost-efficient alternative to rigid-flex PCBs and are ideal for applications with moderate bending requirements.