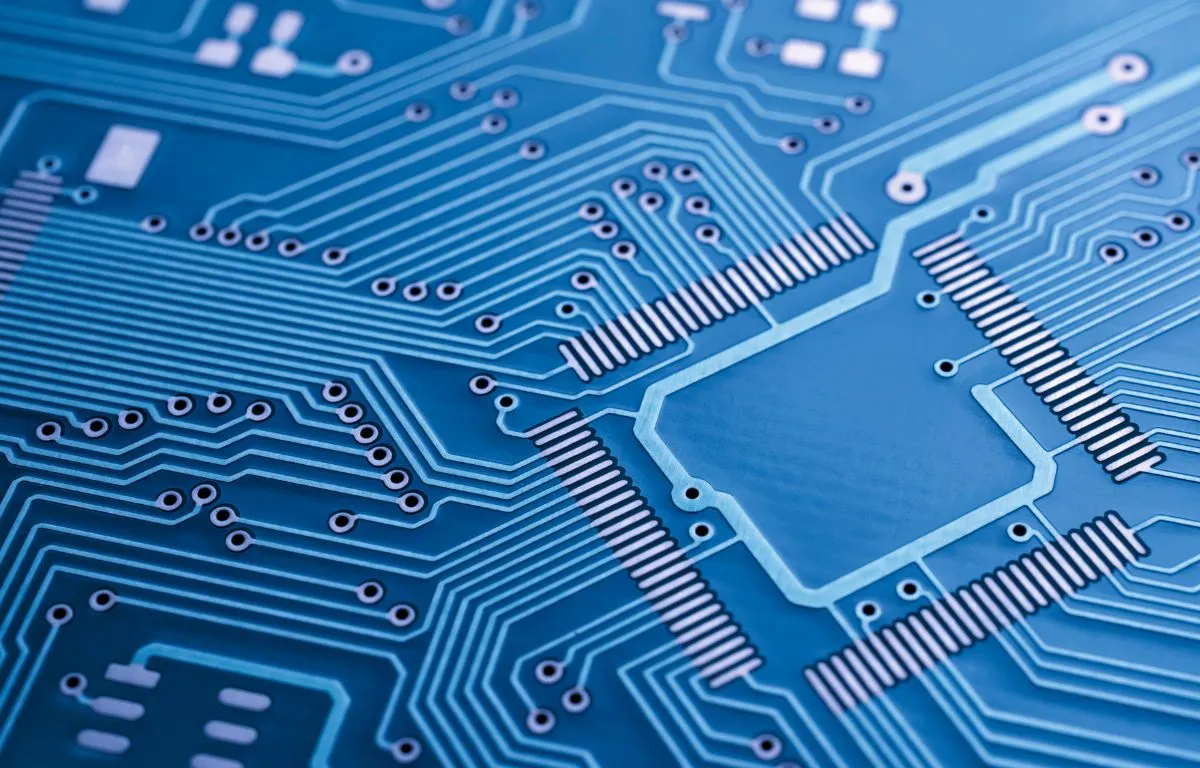

Highly Reliable PCBs for Industry & Automation

Industrial PCBs are specially designed circuit boards used in production plants, control systems, power electronics, and industrial sensors. They must withstand extreme conditions such as high temperatures, mechanical stress, humidity, and electromagnetic interference (EMI). With increasing digitalization and automation (Industry 4.0), powerful, durable, and robust PCBs are becoming ever more important.

.webp)

Applications

PCBs are used in industry for a variety of applications, including automation systems, machine controls, robotics, and process monitoring. They are crucial for controlling sensors, actuators, controllers, and communication systems in manufacturing plants. PCBs enable precise control and optimization of machine processes and contribute to increased efficiency and error prevention in production. They are also embedded in industrial PCs and monitors as well as in systems for data transmission and processing.

-

Automation Systems

In manufacturing facilities, PCBs enable control of automated processes to increase efficiency and productivity.

-

Machine Controls

Precise regulations for production machines are possible thanks to powerful PCBs that continuously monitor operating parameters.

-

Robotics

Industrial robots rely on PCBs to control movements, perform tasks, and coordinate complex operations.

-

Process Monitoring

Sensors on PCBs capture and analyze production data in real-time to minimize errors and ensure quality.

-

Energy Management Systems

Efficient distribution and use of energy in large industrial plants are optimized by intelligent PCB-controlled controls.

Frequently asked questions

-

High-quality materials like FR-4 High-Tg, polyimide, Rogers, PTFE and metal core PCBs are ideal for industrial applications.

-

With copper thicknesses up to 400 μm, they enable the safe operation of high-current applications, switch-mode power supplies & converters.

-

Through conformal coating, special protective lacquers & hermetic potting techniques, PCBs can be protected against environmental influences.

-

Our industrial PCBs meet strict IPC-A-600 & IPC-6012 Class 3 standards for high-performance applications.

-

Yes, rigid-flex PCBs & flexible circuits are perfect for smart automation systems, IoT sensor technology & connected machine controls.

Common Materials used in Industry

In the industry, FR4 materials are often used for most standard PCBs because they are cost-effective and robust. For specialized applications, such as in high-performance machines or under extreme conditions, metal core PCBs or ceramic PCBs are used, offering better heat dissipation capabilities and withstanding high temperatures. In high-frequency applications, such as communication systems, PTFE or Rogers materials are used because they offer excellent properties for signal transmission. Flex PCBs find their place in applications requiring a flexible form or integration in confined spaces.

- Ceramic PCB

- Ceramic PCBs consist of ceramic substrates such as aluminum oxide (Al�02O�03) or aluminum nitride (AlN), offering extremely high thermal conductivity, excellent electrical insulation, and outstanding mechanical stability. Compared to conventional FR-4 PCBs, ceramic PCB board are ideal for high-power applications requiring efficient heat dissipation and exceptional reliability.

- FR-4 PCBs

- FR-4 is the most widely used base material in PCB manufacturing. It is a glass-reinforced epoxy laminate offering high mechanical strength, excellent electrical insulation, and very good temperature resistance. The term "FR" (Flame Retardant) indicates that the material is flame resistant and meets the UL94 V-0 standard.

- Rogers PCB

- Rogers PCBs are made from high-quality, high-performance laminates specifically designed for high-frequency and high-speed applications. Unlike standard FR-4 materials, Rogers laminates offer improved dielectric constant, lower losses, and better thermal performance. These properties make them the ideal choice for RF (Radio Frequency), microwave communication, and high-frequency power electronics.

- Semiflex PCB

- Semiflex PCBs are partially flexible circuit boards that can be bent over defined areas while the rest of the board remains rigid. This technology allows space-saving, reduces connectors, and improves the reliability of electronic systems. Semiflexible PCBs are often used as a cost-efficient alternative to rigid-flex PCBs and are ideal for applications with moderate bending requirements.